Example ring using a ø40 mm full round profile – also possible with groove/plow for LED

Bending a ø40 mm full round profile to a radius of 50 cm means bending to its limit. It is possible, however, without cutting the profile in half if the following guidelines are observed:

- using a full round profile with diagonal joints (e.g. item number P-40);

- increasing wood moisture content to 12% (according to our instructions - See 2. How to bend Bendywood® and moisten it if needed);

- using a brittle glue to avoid distortion of the ring on the glue line.

How to proceed:

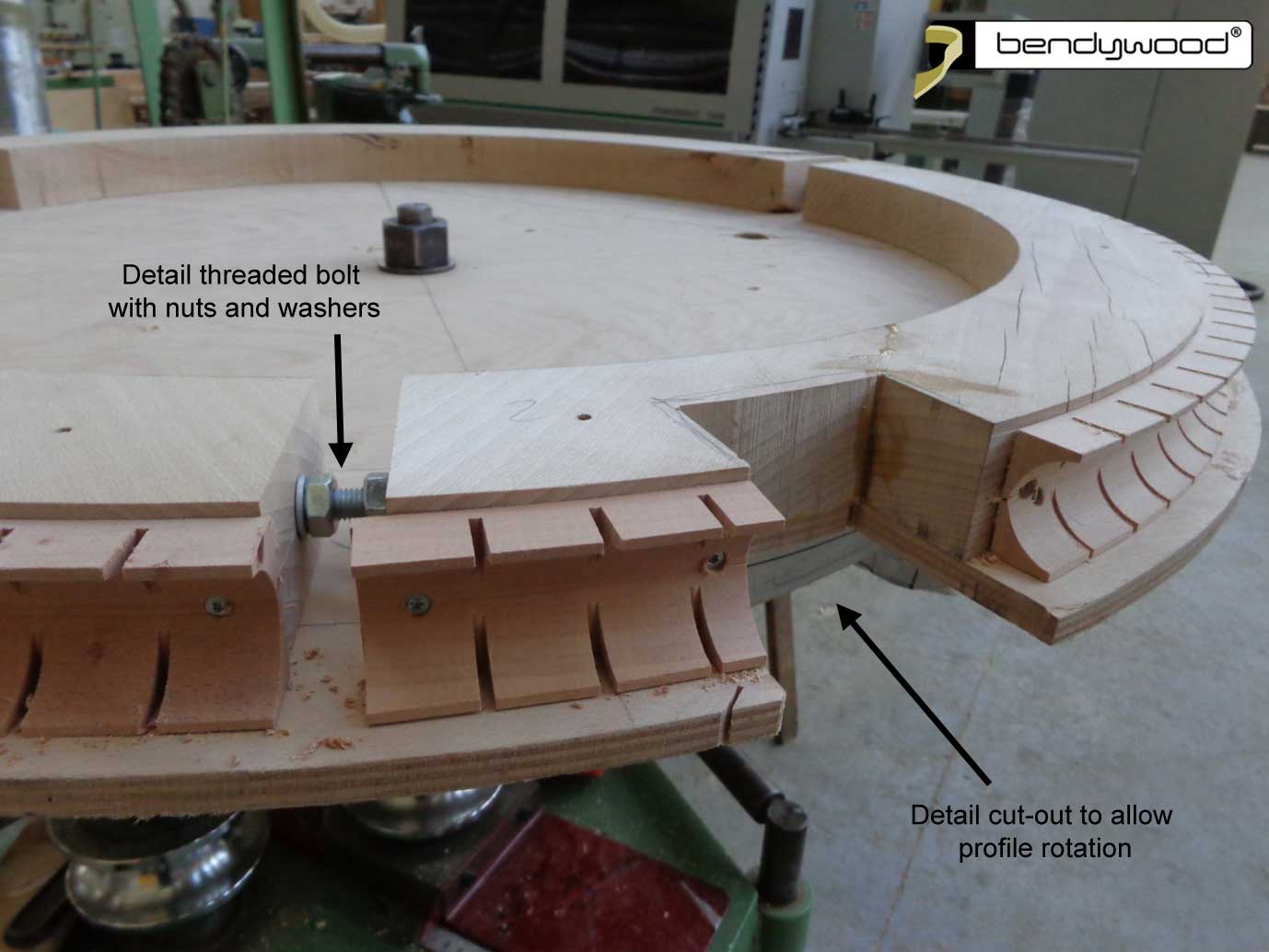

- Build a bending mould in 3 parts (see photo) with radius 50 cm. Put the 3 parts together using threaded bolts, nuts and washers.

Fix matching Bendywood® bending moulds on the edge of the bending mould. Make sure to provide them with vertical incisions that will allow for easier bending. Prepare the same matching Bendywood® bending moulds for the pressing from the outside. Matching Bendywood® bending moulds are available for delivery.

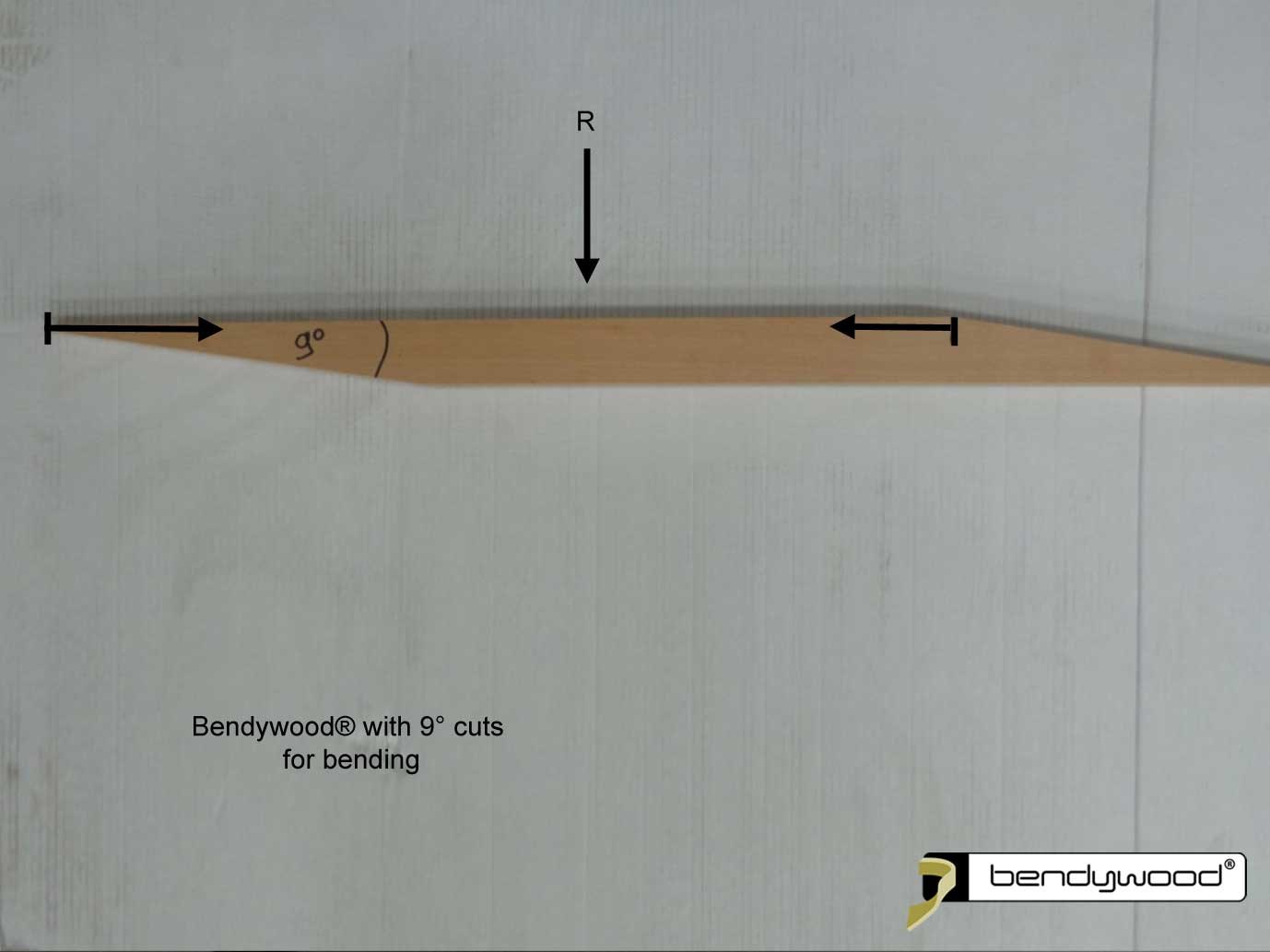

Make a cut-out in one of the 3 bending mould parts to allow for profile rotation to match the 9° cut faces, if needed. - Cut the bending handrail to length by means of a sharp 9° cut on both ends. Please also click through to "Mould for 9° cuts".

How to calculate exact profile length to be bent:

When Bendywood® is bent, it gets compressed / it shrinks on the inside and it stretches on the outside. Only the length of the center line doesn’t change and this should be considered when cutting to length.

The length of a ø40 mm full round profile for a ø 1 meter ring therefore doesn’t equal: diameter x 3,14, but (diameter + 2 cm each side) x 3,14.

Therefore the correct matching bending length for a ø1 m ring is (100 cm + 4 cm) x 3,14 = 326,56 cm.

Once bent, this length + the final part with 9° cut perfectly fits onto the mould with R = 50 cm. -

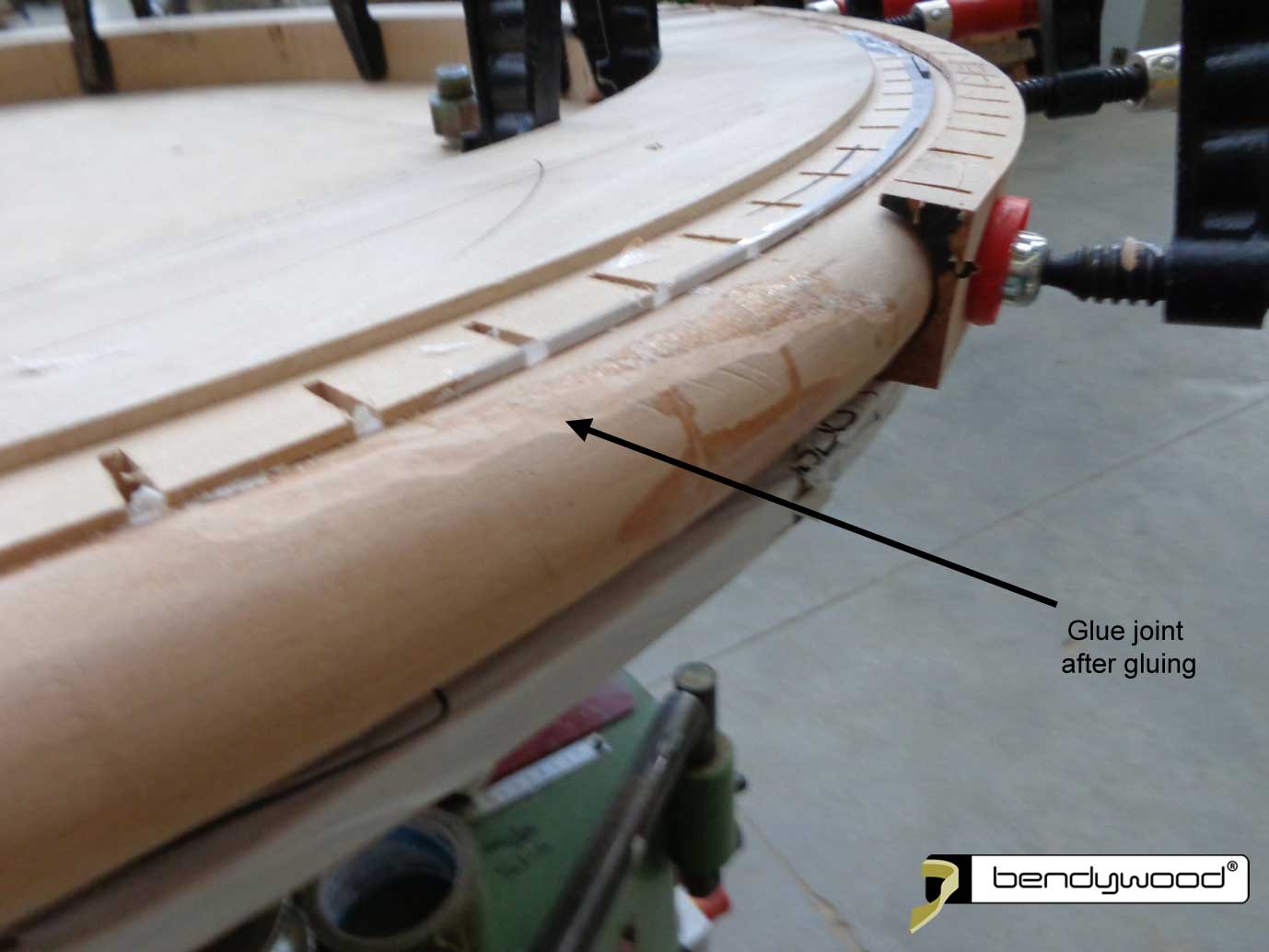

Where both ends of the ø40 mm full round profile will be glued together, the matching Bendywood® bending moulds that have been fixed to the edge of the bending mould should be covered with adhesive tape.

- Start bending the ø40 mm full round profile from one side along with the external matching Bendywood® bending mould and press everything well against the bending mould using clamps. If needed, rotate the round profile at the cut-out spot in order to match the 9° cut ends and glue them together.

- Then loosen the nuts on the bolts in order to prevent the ring from getting jammed on the bending mould.

- Once the glue has dried the ring can be taken from the mould and can be sanded.

Only Bendywood® renders these kinds of jobs possible!

The ø40 mm full round Bendywood® profile (item number P-40) is available in:

- beech, ash, maple, oak and walnut;

- lengths up to 6 m.