Bendywood® bending handrails are:

- in solid hardwood

- in full sizes / not in multiple layers

- already machined, ready for bending

Our stock product range contains:

Bendywood® handrails can be bent up to a radius of 20 times the profile's cross section. A 40 mm round profile up to a radius of 800 mm, for instance, and a 50 mm profile up to a radius of 1.000 mm.

In order to be able to bend up to these limits a wood moisture content of about 12% is indispensable.

See part 2. How to bend and moisten Bendywood®.

ATTENTION:

Bendywood® will slightly open up when taken off the mould. Therefore, in order to obtain the requested final radius, Bendywood® needs to be “overbent”, i.e. the radius needs to be kept proportionally smaller. Also see on our website under “Spring-back after being taken from the mould”.

BENDING JUST BY HAND:

a. Bending an ascending handrail around a flat mould:

this is the easiest and best solution for spiral staircases!

See video for a round handrail:

See video for a round handrail with flat bottom side:

- The transport costs are significantly lower than the costs for shipping long straight sections.

- It is possible to perform the upwards bending later, when mounting the bending handrail.

- It is also possible to combine normal wood with Bendywood®.

- Also lengths up to 13 m are feasible, as special production.

- Handrails with groove/plow are also possible.

The following video shows how such a handrail is installed upwards:

b. Bending an ascending handrail around an ascending mould / assembly support:

If it is not possible to pre-bend around a flat mould, you can build a mould as shown in the pictures below.

BENDING BY USING A RING ROLLING BENDING MACHINE:

- Solely the bending handrails with diagonal joints

can be pre-bent with a ring rolling bending machine (up to a radius of 1 : 30), as only diagonal joints can endure the mechanical stress of a bending machine. A handrail with a diameter of 40 mm, for instance, can be bent up to a radius of 1.200 mm. The final bending - if necessary - up to a radius of 1 : 20 should be carried out by hand around a mould or on the banister. See the following video to this:

can be pre-bent with a ring rolling bending machine (up to a radius of 1 : 30), as only diagonal joints can endure the mechanical stress of a bending machine. A handrail with a diameter of 40 mm, for instance, can be bent up to a radius of 1.200 mm. The final bending - if necessary - up to a radius of 1 : 20 should be carried out by hand around a mould or on the banister. See the following video to this:

- Tighten the bending radius progressively, letting the handrail run through the rollers of the bending machine not more than 3 times. Bear in mind that the ring rolling bending machine also rolls the wood and rolled Bendywood® will reach its limit of flexibility more quickly. Consequently, a 40 mm thick handrail, for instance, can only be bent up to a radius of 1.200 mm by machine, then you should continue by hand.

- The bending handrails with normal joints

CANNOT be bent with a ring rolling bending machine.

CANNOT be bent with a ring rolling bending machine.

HOW TO BEND NON-ROUND HANDRAILS UPWARDS ?

All handrails turn on their own axis when being bent upwards. This torsion is not visible in case of a round handrail, as a round profile always looks the same when turned. In case of other profiles or round profiles with a groove/plow it is necessary to compensate for torsion, so that the lower part of the handrail remains below.

It is best to proceed as follows: (in one operation cycle)

First of all bend the handrail on a flat mould. Then clamp it onto the banister (which ideally has a flat steel strip or similar) starting from above. The "turning" should be carried out using a long-arm clamp, which needs to be clamped onto the handrail at a distance of 1,5 m in order to have sufficient leverage. Turn and fix the handrail little by little until the entire handrail rests on the banister.

A few days later – after it has stabilized – the handrail can be taken from the banister to be sanded, stained and varnished. Proceed as soon as possible with the permanent fixing, so that the handrail does not lose its bent form.

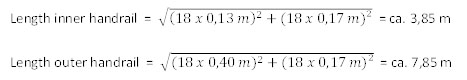

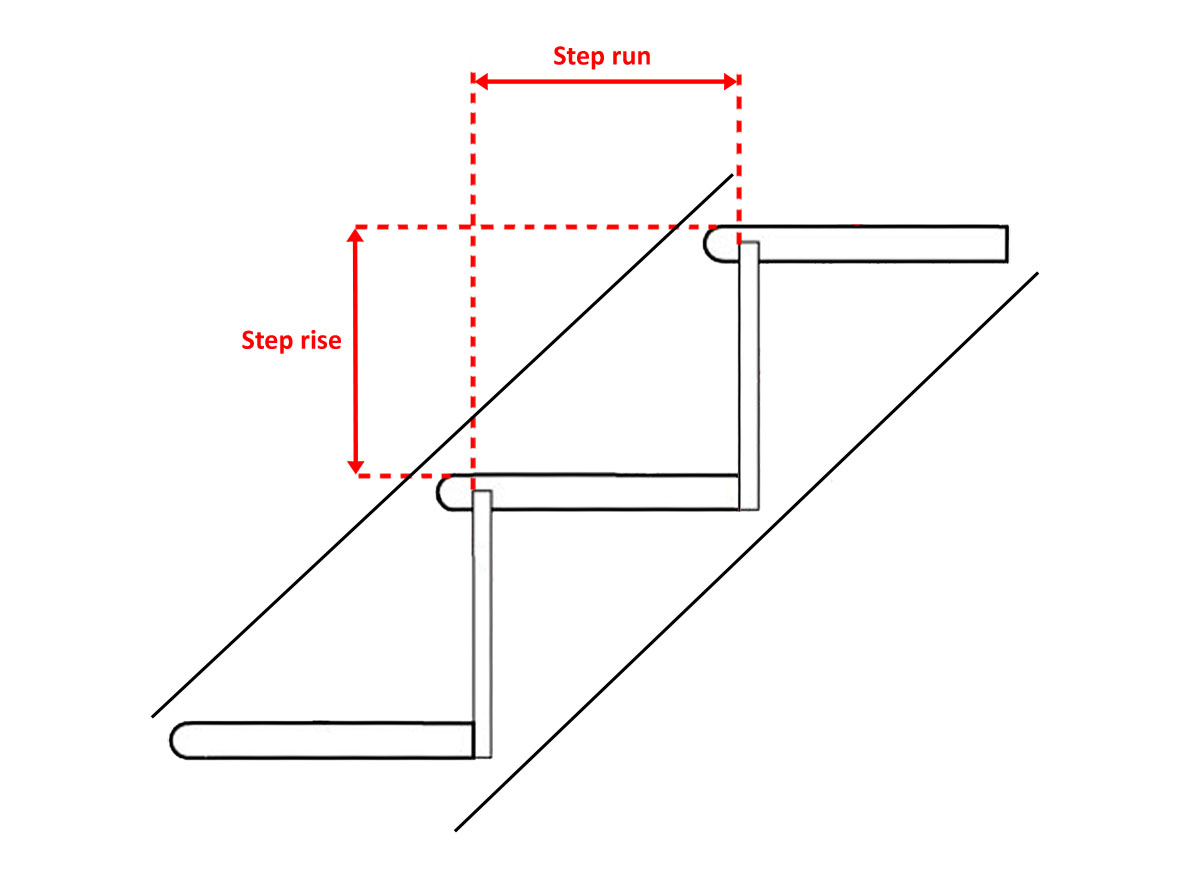

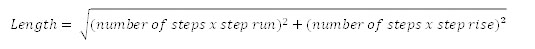

FORMULA FOR CALCULATING THE LENGTH OF A SPIRAL STAIRCASE HANDRAIL:

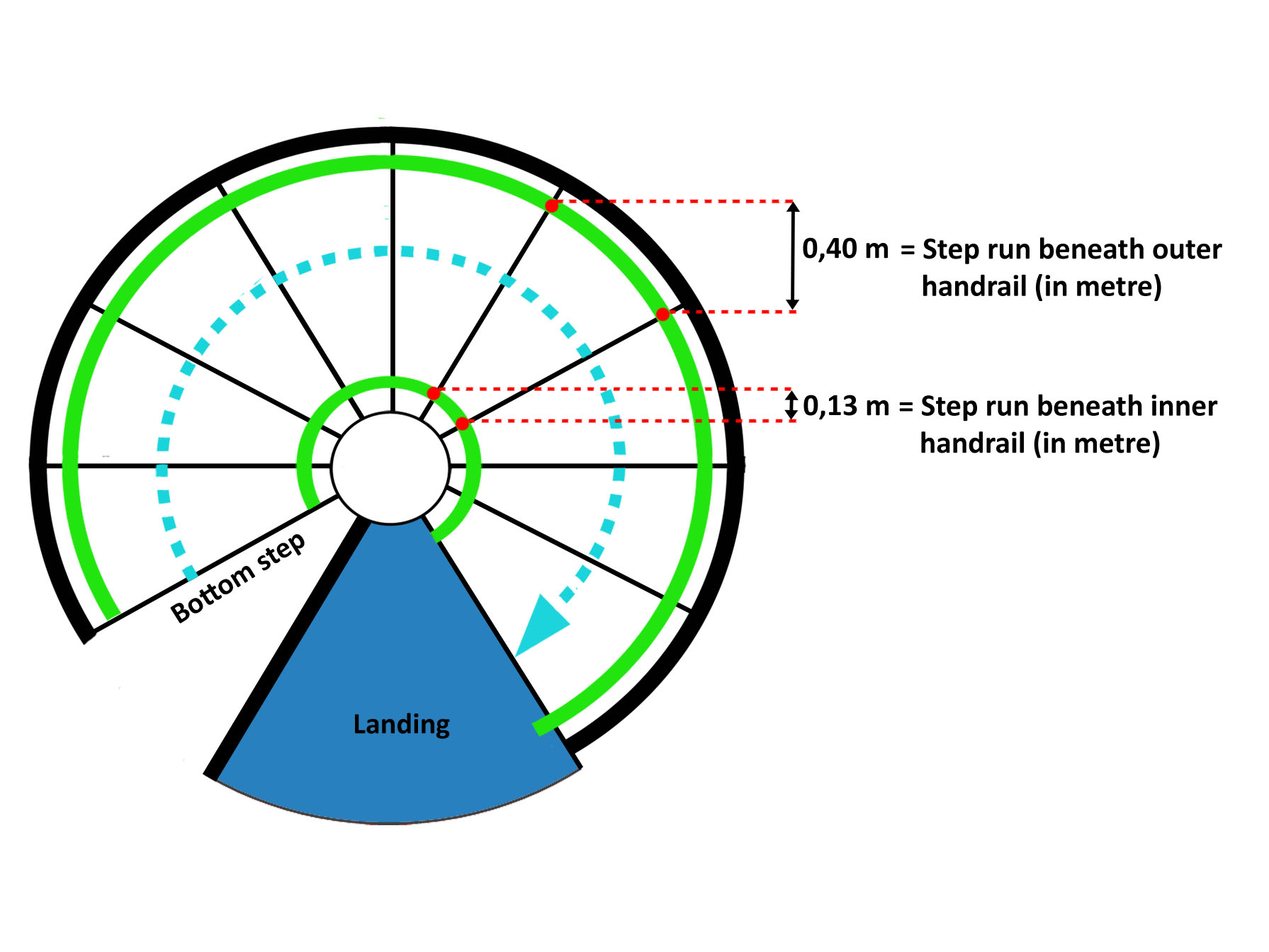

EXAMPLE:

Assuming:

- 18 steps

- Step rise: 17 cm

- Step run beneath inner handrail: 13 cm

- Step run beneath outer handrail: 40 cm